Solintech Oy

Solintech Oy is a high quality engineering company with flexible and fast service

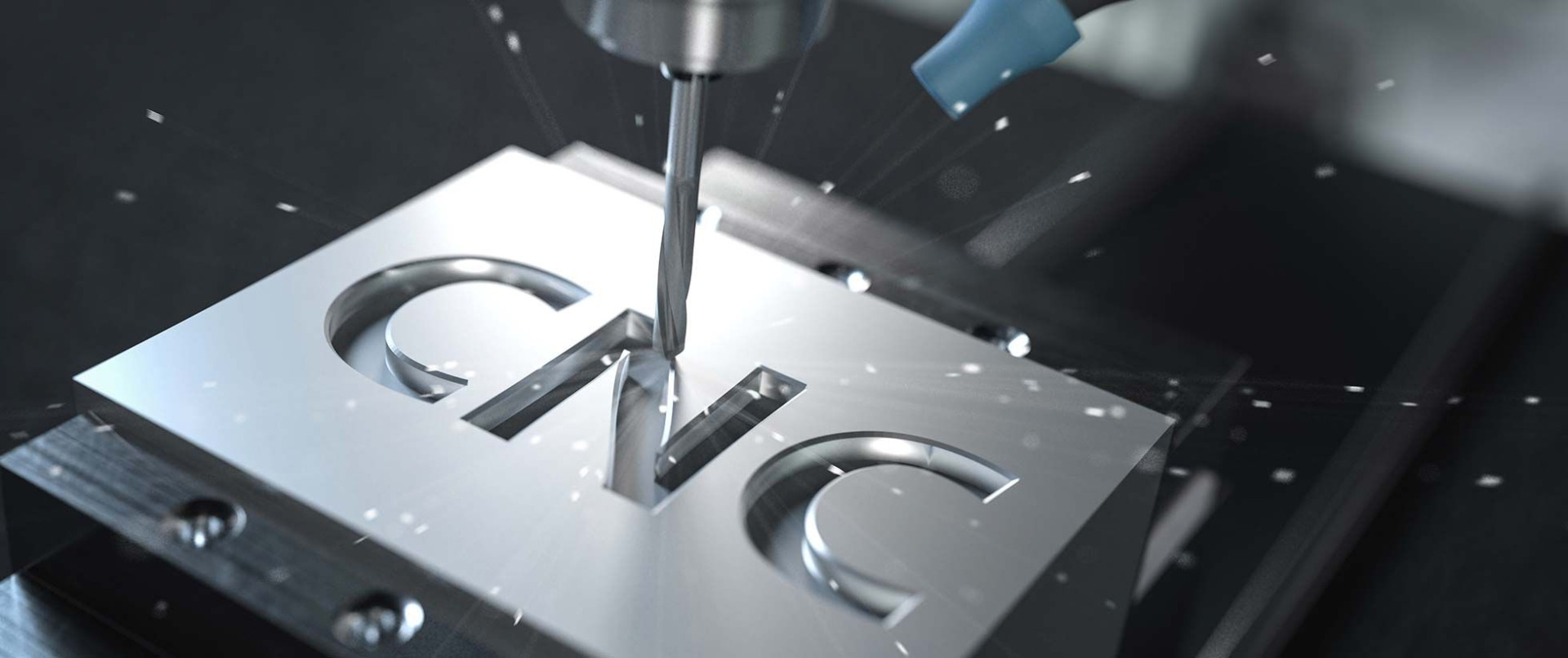

CNC machining, 3D modelling and assembly from Iitti

Our custom machine shop was established in 2004 in Iitti, from where we still serve the whole country. Our services include CNC machining, 3D modelling and assembly, where we manufacture metal and plastic tools, spare parts and machine parts, mainly for the industrial sector. We also provide maintenance services. Find out more about our services and benefit from our partnership in your business!

We offer a flexible service that adapts to our customers' needs, even in the face of sudden changes and situations. We are able to make deliveries within a short timeframe.

High-quality machinery and meticulous workmanship

Our machine tools and other equipment are state-of-the-art, allowing us to produce small and large series and one-off parts according to your needs. Our production is supported by SOLIDWORKS 3D CAD mechanical design software and ZW3D CAD/CAM hybrid software. Our staff consists of experienced machinists with good knowledge of materials and machinery. The customer's order is always completed with a precise, economical and careful end result, certainly meeting all quality requirements.

Machining, 3D modelling and assembly from Iitti

We manufacture moulds, spare parts, backing devices, assembly and maintenance work, etc.

Our on-demand machine shop in Iitti offers 3D modelling, CNC machining and assembly. We offer tool and part manufacturing as well as assembly and maintenance services. Take a look at our production and let us know what kind of manufacturing you need, so we can plan the best possible implementation and prepare a good offer. Contact us!

We offer a flexible service that adapts to our customers' needs, even in the face of sudden changes and situations. We are able to make deliveries within a short timeframe.

Our products include

- Various thermoforming moulds for the packaging industry

- Spare parts for the paper and process industry

- Sub-assembly, assembly and maintenance of beverage packaging return line back-ups

- Series of different sizes, from single prototypes to larger, repetitive deliveries

- We use metals and plastics in our manufacturing. Design and modelling is done using SolidWorks 3D mechanical design software, with machining using VX CAD/CAM hybrid software.

Reliable deliveries

Our deliveries are reliable and, if necessary, fast. Our production is flexible and works according to the customer's needs. Ask for manufacturing for your own products or request a direct quotation for machining, 3D modelling or assembly services. We are available to our customers from our machine shop in Iitti, Haapakimola, throughout the country.

Machining with state-of-the-art equipment in our machine shop in Iitti

CNC machines and our other machinery and equipment

High-quality machining requires not only professional skills but also high-quality machines. At Solintech Oy, Iitti, we have a comprehensive range of machines for small, large, serial and individual productions. Contact us and take advantage of our partnership! We offer a fast and flexible service.

Mazak Nexus 410A, three-axis vertical machining centre, year 2006

- Movements X560, Y410, Z500

- Table size 900 mm x 410 mm

- Spindle speeds 40 ... 12000 rpm

- Spindle diameter 70 mm

- Tool changer with 30 tool magazine

- Spare tool system

Mazak QT SMART 200ML 1000U lathe equipped with LNS Quick Load Servo 80, 2015

- Maximum rotation diameter on guides 660 mm

- Maximum turning diameter 360 mm

- Turning length 1 055 mm

- Bar capacity (with standard support) 65 mm

- Maximum piece weight, chuck work (including chuck) 300 kg

- Maximum piece weight, shaft work (including chuck) 500 kg

- C-axis longitudinal movement 555 k/min

- C-axis indexing 0,0001 °

- NC end-piece, programmable travel 1075 mm

- Rotating tools

Mazak QuickTurn 10 lathe with FMB turbo 5-42 XT tank carriage and nose spindle, year 1996

- Max. chipping diameter 160 mm

- Max. chipping length 250 mm

- Maximum bar diameter 42 mm

- 8-seat drum turret

- X-travel 100 mm

- Z-travel 290 mm

- Rapid traverse speed 30 m/min

- Bianco 350 CNC band saw

- Cutting capacity wheel 260 mm, square 220 mm

Other machines and equipment

- Easyshrink tool setting device

- Kramer Allrad 418 wheel loader

- Hyster electric forklift

- Band saw

- Belt sander

- Part washer

- Various hand tools

Our CAD/CAM software supports all the most common file formats such as IGS., STEP., STL. and PARASOLID.

Contact us

CNC machining, 3D modelling, assembly and maintenance from us

We are the partner of choice for many companies in need of high quality machining. We service the entire country. Find out more about our activities and take advantage of our expertise!

Peltolantie 8,

47310 HAAPAKIMOLA

Business ID: 1897581-8

Tomi Peltola

040 587 2533

tomi.peltola@solintech.fi

Chairman of the Board of Directors

Tools, materials, customer cooperation

Janne Peltola

040 538 5522

janne.peltola@solintech.fi

Managing Director

Financial management, customer relations

Solintech Oy

© 2025 Solintech Oy

implementation by kymit.fi